Caught in the Web: How to Spin Complexity into a Supply Chain Advantage

- Edgar Cetina Rodríguez

- Oct 3, 2024

- 5 min read

We often hear that modern supply chains are complex and are only growing more complex. This complexity, we are told, adds cost to a supply chain and makes it more difficult to manage. Therefore, we should all look to mitigate or minimize complexity, seeking maximum simplicity in our logistics and operations. However, what exactly does “complexity” mean in the context of supply chain? It’s more than just the number of moving parts. Complexity refers to the intricacies and interdependencies between suppliers, logistics, regulations, and customer expectations. As supply chains stretch across borders, involve multiple tiers of suppliers, and rely heavily on technology, managing them becomes a balancing act. Complexity often introduces challenge, risk, and uncertainty, but also creates opportunities for increased growth and resilience, especially when handled with foresight and agility.

The Origins of Supply Chain Complexity

The Impact of Globalization

One of the major drivers of modern supply chain complexity is globalization. As companies source materials from across the globe and cater to international markets, they face challenges like fluctuating tariffs, differing regulatory environments, political instability, and extended lead times. This geographic expansion brings with it an increase in suppliers, modes of transportation, and warehouses, all of which must be managed efficiently.

Globalization also increases the likelihood of supply chain disruption. An issue in one part of the world - whether political unrest or a natural disaster - can reverberate through the entire chain, affecting production schedules, inventory levels, and ultimately, customer experience. Navigating these complexities and building in redundancies requires not just strategic foresight but also real-time data to make informed decisions quickly.

Consumer Demand and the Rise of E-Commerce

Another layer of complexity is added by the shifting landscape of consumer demand, particularly with the rise of e-commerce. Today’s consumers expect more: faster deliveries, personalized products, and seamless experiences across channels. This demand-driven market pushes companies to adopt just-in-time delivery models and manage increasingly fragmented orders.

Unlike traditional brick-and-mortar retail, e-commerce introduces variables like last-mile delivery, reverse logistics (returns), and multi-channel fulfillment, all of which compound supply chain complexity. The ability to deliver quickly, without overstocking or running out of inventory, becomes a key differentiator. Meeting these expectations while managing costs requires flexibility, visibility, and a keen understanding of demand patterns.

A Symptom of Complexity: The Bullwhip Effect

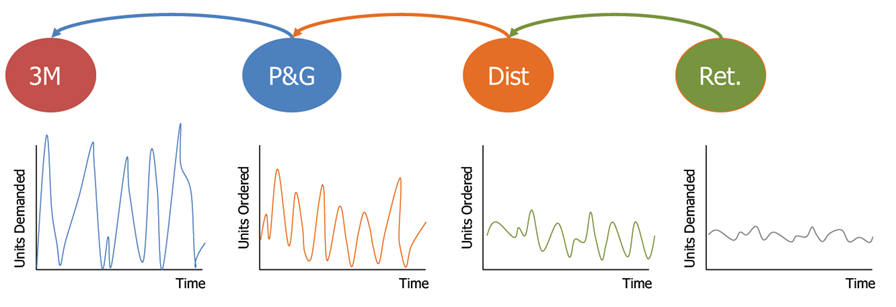

One classic phenomenon in supply chains that exemplifies how complexity can spiral out of control is the bullwhip effect. Small fluctuations in consumer demand can cause disproportionately large fluctuations in supply chain orders and inventory levels as they ripple up the chain.

When demand forecasts are inaccurate, even by small margins, suppliers upstream may overreact, increasing production and stockpiling inventory to avoid stock outs. This leads to inefficiency, excess inventory, and higher costs. The further up the supply chain you go, the more exaggerated these swings become, as illustrated in the image below.

Bullwhip Effect Example

As you start analyzing the demand patterns in the image, notice how the demand for the retailers is steady and the coefficient of variation (variability) seems small. As you travel upstream, from the distributor to the manufacturer (P&G) and finally to the supplier (3M) you can see how the coefficient of variation increases. This bullwhip effect can have the following impacts:

Increased manufacturing costs

Higher inventory levels and costs

Longer replenishment lead times

Lower product availability

Lower supply chain profitability

Data and Analytics: The Key to Mastering Complexity

In the face of all this complexity, how can companies regain control? The answer lies in data and analytics. Near real-time data from various points in the supply chain - whether inventory levels, production rates, or supplier performance - can provide the necessary insights to make informed decisions. This data provides transparency and visibility across the entire supply chain, allowing businesses to anticipate disruptions, make informed decisions, and react faster to changes. By having access to detailed information from suppliers, transport providers, and customers, companies can improve their forecasts, avoid overstocking or stockouts, and reduce lead times. This near real-time insight transforms what once felt like chaos into a more predictable and manageable system.

Leveraging this data, advanced analytics, powered by machine learning and artificial intelligence, can help forecast demand, optimize routes, and identify potential risks before they escalate into crises. By analyzing both historical patterns and near real-time information, companies can build more resilient supply chains that respond dynamically to changes in demand, supply, or external disruptions.

Additionally, advanced communication technologies streamline interactions between different actors in the supply chain. With better coordination between suppliers, manufacturers, and distributors, miscommunication is reduced, and inefficiencies are minimized. Cloud-based platforms, such as Microsoft Fabric, facilitate seamless collaboration across borders and time zones, ensuring all stakeholders are working from the same data and can respond to fluctuations in demand or supply disruptions together, reducing delays and costs. Check out Jesús’ blog “Woven Together: Integrating Microsoft Fabric into Supply Chain” where he elaborates on how these systems expand the visibility of your supply chain and improve the communication and coordination amongst players.

Embracing Complexity with Agility

Embracing Complexity: A Competitive Advantage

While data and analytics can help you reduce operational complexity, it is sometimes valuable to instead embrace it. Complexity in the supply chain, when managed effectively, can become a significant competitive advantage. Companies that embrace complexity are better positioned to serve diverse markets, meet evolving customer needs, and navigate global challenges. In a world where customization, agility, and speed are becoming crucial differentiators, the ability to operate within a complex network allows companies to offer more personalized services and products without sacrificing efficiency.

Managing complexity requires agility, but it also provides flexibility and resilience. For example, an organization with a robust, multi-tiered supply chain can respond faster to disruptions or shifts in demand, offering alternative sourcing or production methods when needed. The ability to pivot quickly, whether it’s to meet a surge in customer demand or overcome a supplier disruption, is what separates leading companies from those struggling to adapt to today’s competitive market.

Moreover, complexity enables companies to better serve diverse and global markets. With the rise of customization and demand for personalized services, having a complex, well-managed supply chain allows businesses to offer a broader range of products and services without sacrificing efficiency. The ability to meet shifting customer expectations, handle varying regulations, and manage cross-border logistics means companies can capture new market opportunities and expand their customer base.

Supply chain complexity is here to stay. But rather than being an obstacle, it can be a source of competitive advantage, if managed well. Globalization, shifting consumer expectations, and rising risks mean supply chains will only get more complicated. However, with the right tools, strategies, and a focus on data-driven decision-making, companies can navigate this complexity and turn it into an opportunity for innovation and growth.

In the end, it’s not just about simplifying the supply chain—it’s about mastering its complexity. The organizations that embrace agility, foster collaboration, and leverage technology will be the ones that not only survive but thrive in this ever-evolving landscape.

Comentarios